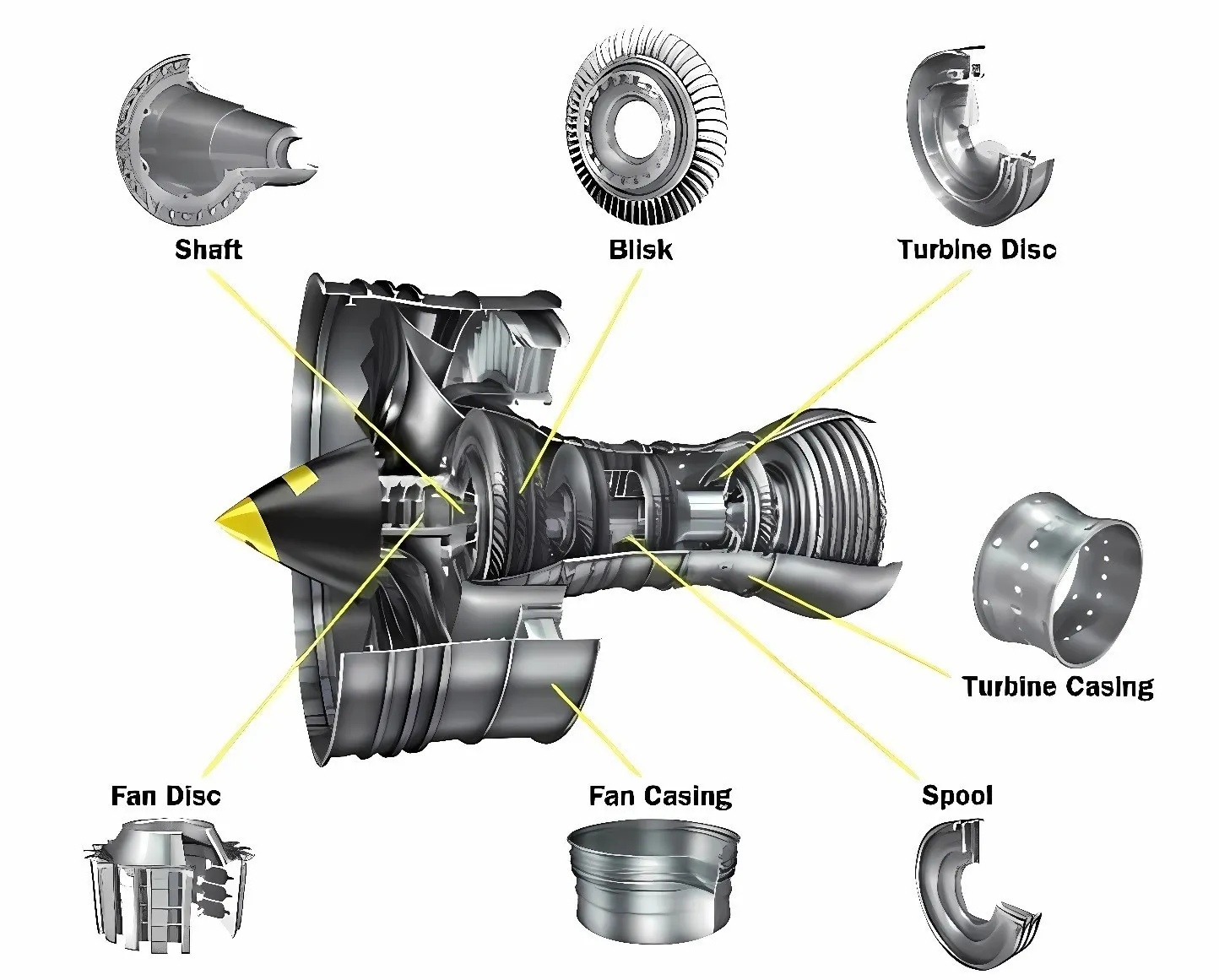

Precision manufacturing for critical flight hardware, from hot-section turbine blades to structural housings.

High-pressure and low-pressure turbine blades manufactured via precision casting (Equiaxed, Directionally Solidified, and Single-Crystal).

Forged and machined blades for cold-section applications.

High-precision forged disks and shafts engineered for extreme rotational speeds and temperatures.

Main engine shafts produced with superior mechanical integrity.

Stator components and nozzle guide vanes with complex internal cooling geometries.

Hydroformed and superplastic-formed thin-walled components for high-efficiency combustion modules.

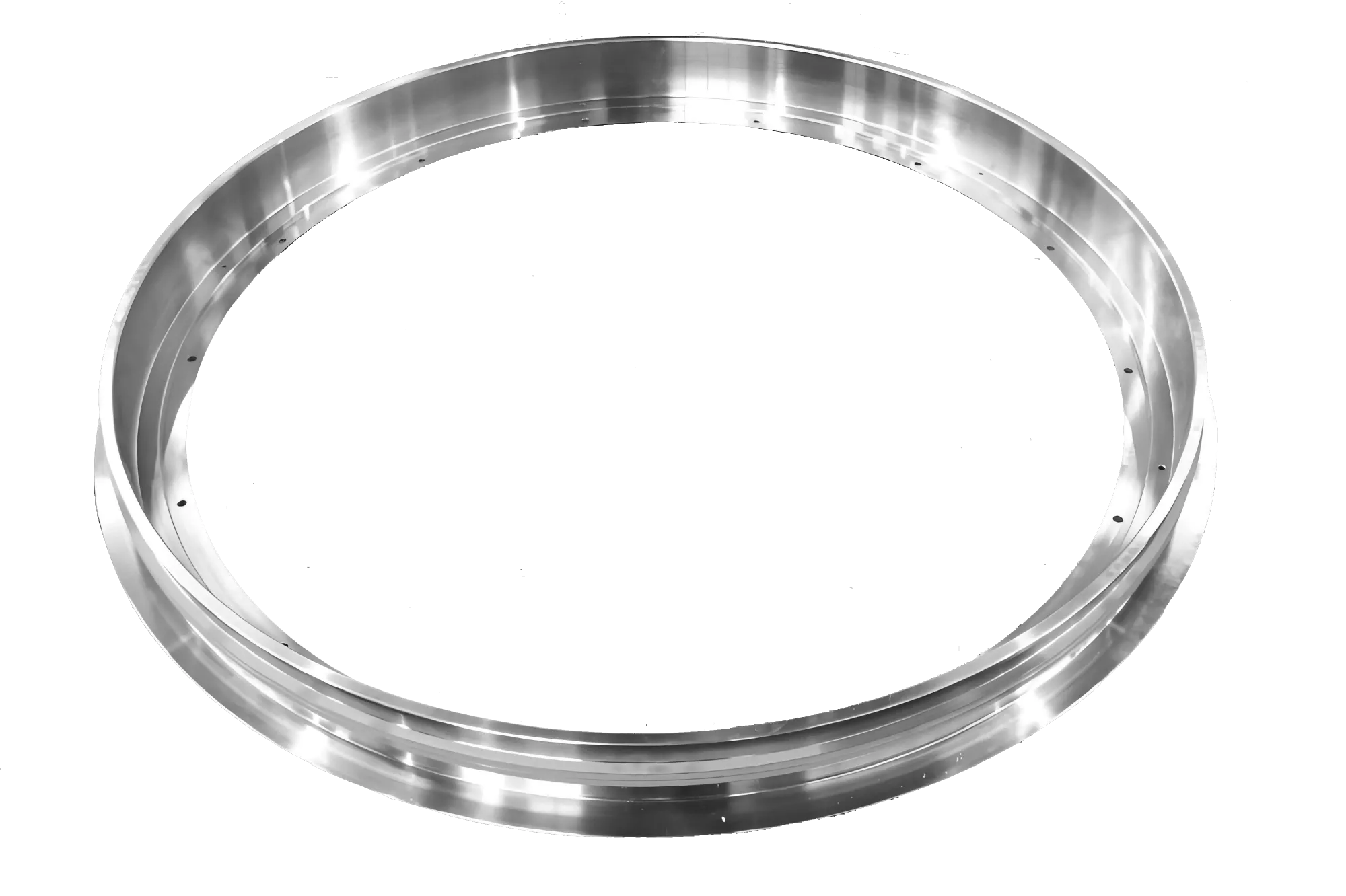

Large ring-rolled and machined casings, shrouds, and air seals.

Load-bearing hot-section components and lightweight titanium structural elements.