Our Inspection and Quality Assurance operations deliver unmatched quality assurance solutions to ensure that all components meet the most stringent aerospace and industrial standards. We utilize state-of-the-art equipment and certified procedures to maintain zero-defect integrity, product reliability, and performance of critical components.

We offer a complete set of NDT methods for subsurface flaw/crack inspection and internal components, including:

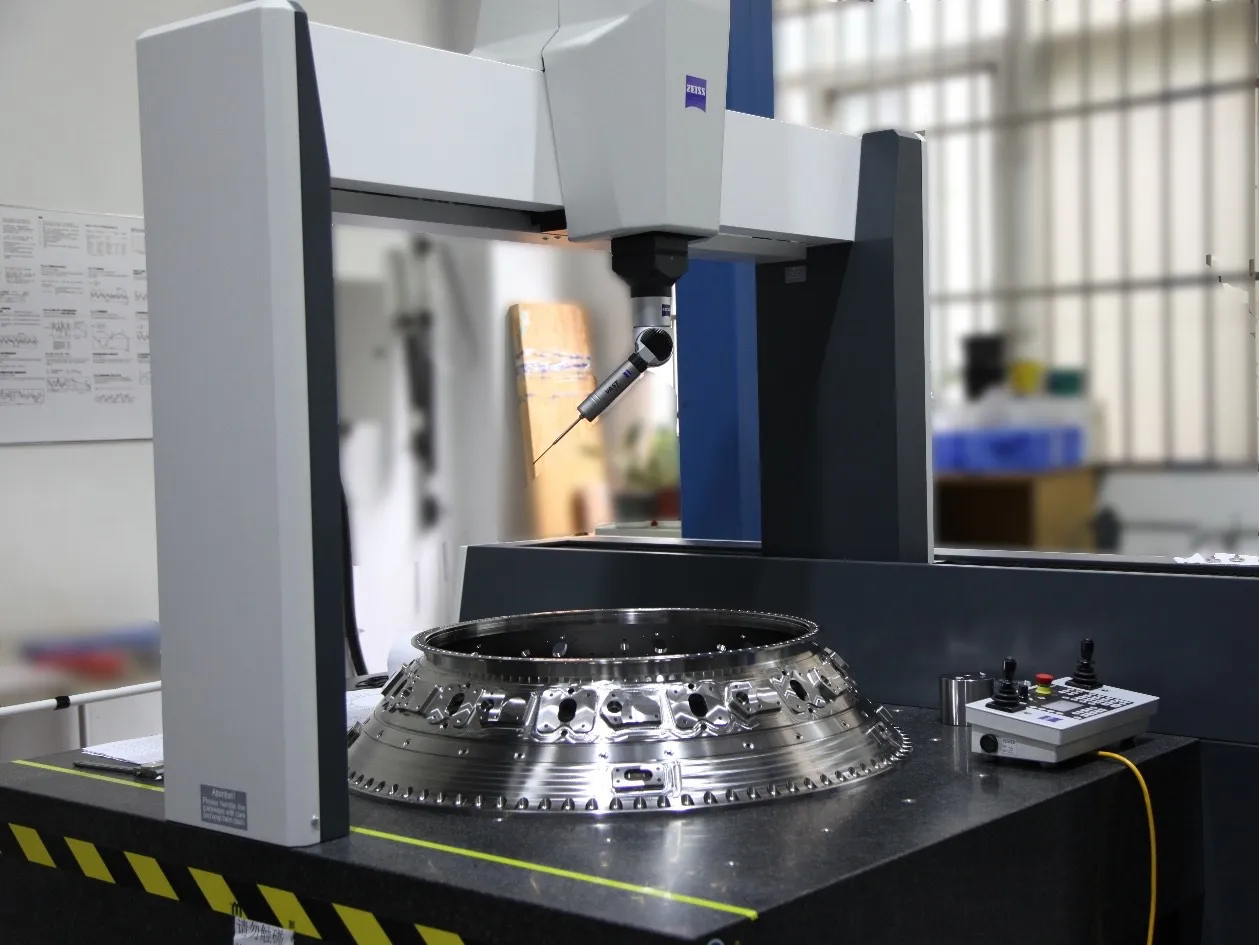

We perform complete dimensional and functional inspections for all parts, machines, and surfaces, including:

Industry-certified laboratories for stringent aero-engineering standards including AS9100 and customer-specific requirements, using AS/ASTM and AMS standards.