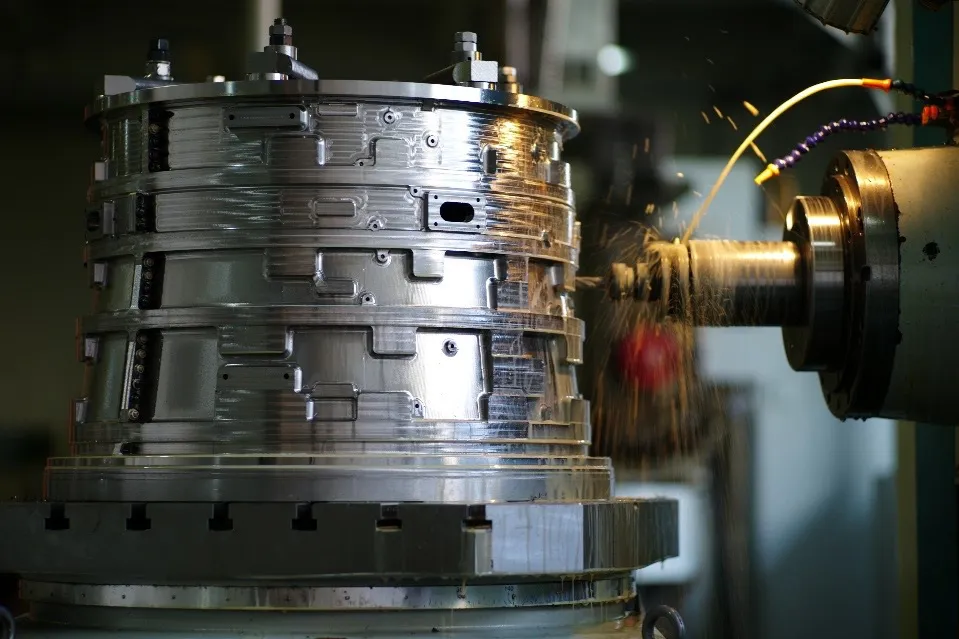

Our Machining Division provides high-precision processing for complex aerospace and industrial components, ensuring each part satisfies strict dimensional, surface-quality, and functional requirements. We integrate advanced equipment, skilled technicians, and rigorous inspection routines, upholding repeatability and traceability across a wide range of materials and geometries.

Using our comprehensive suite of high-performance equipment, we can machine complex equiaxed, directionally solidified (DS), and single-crystal (SX) castings, along with forged, formed, and other specialized materials and components, which is supported by:

Our machining operations adhere to strict tolerances and surface-finish requirements across all steps: